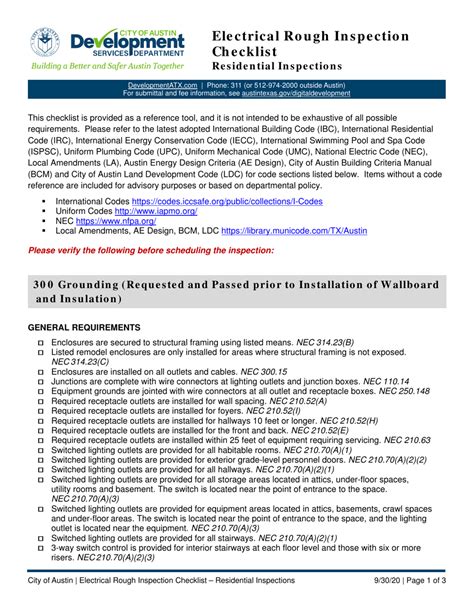

Electrical Rough In Inspection Form

Introduction to Electrical Rough In Inspection

The electrical rough-in inspection is a critical step in the construction process, ensuring that the electrical system is installed correctly and safely. This inspection typically occurs after the electrical wiring, outlets, switches, and other components have been installed, but before the walls are closed up with drywall. In this article, we will discuss the importance of the electrical rough-in inspection, the components involved, and provide a sample inspection form.

Importance of Electrical Rough In Inspection

The electrical rough-in inspection is essential for several reasons:

- Safety: It ensures that the electrical system is installed correctly, reducing the risk of electrical shocks, fires, and other hazards.

- Compliance: It verifies that the electrical system meets local building codes and regulations.

- Quality: It helps to identify any defects or issues with the electrical system, allowing for corrections to be made before the walls are closed up.

Components Involved in Electrical Rough In Inspection

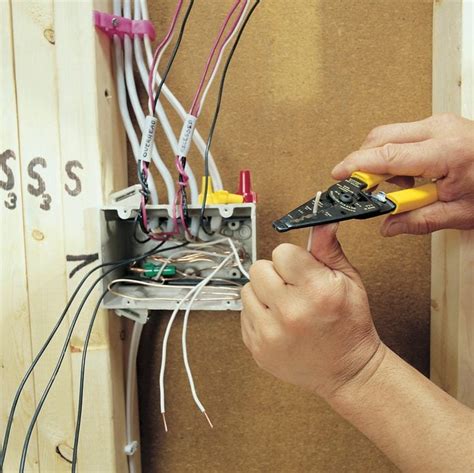

The electrical rough-in inspection involves checking various components of the electrical system, including:

- Wiring: Checking that wires are properly sized, insulated, and routed.

- Outlets and switches: Verifying that outlets and switches are installed correctly and meet code requirements.

- Panelboards and circuit breakers: Ensuring that panelboards and circuit breakers are installed and configured correctly.

- Grounding and bonding: Checking that grounding and bonding systems are properly installed and connected.

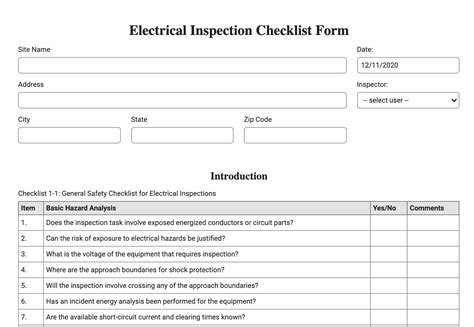

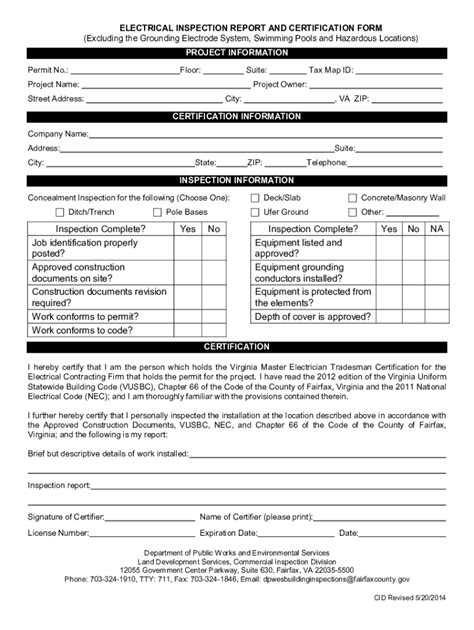

Electrical Rough In Inspection Form

The following is a sample electrical rough-in inspection form:

| Component | Inspection Criteria | Pass/Fail |

|---|---|---|

| Wiring | Proper sizing, insulation, and routing | |

| Outlets and switches | Correct installation and code compliance | |

| Panelboards and circuit breakers | Correct installation and configuration | |

| Grounding and bonding | Proper installation and connection |

💡 Note: This is a sample inspection form and should be modified to meet the specific needs of your project.

Conducting the Electrical Rough In Inspection

To conduct the electrical rough-in inspection, follow these steps:

- Review plans and specifications: Familiarize yourself with the electrical plans and specifications.

- Visual inspection: Conduct a visual inspection of the electrical system, checking for any defects or issues.

- Use inspection form: Use the inspection form to document your findings and identify any areas that require correction.

- Correct defects: Correct any defects or issues identified during the inspection.

Final Check

After completing the electrical rough-in inspection, conduct a final check to ensure that all components are installed correctly and meet code requirements. This includes:

- Verification of corrections: Verify that any corrections made during the inspection have been completed correctly.

- Final visual inspection: Conduct a final visual inspection to ensure that the electrical system is safe and meets code requirements.

The key points to remember are that the electrical rough-in inspection is a critical step in ensuring the safety and quality of the electrical system, and that it involves checking various components of the electrical system, including wiring, outlets and switches, panelboards and circuit breakers, and grounding and bonding. By following the steps outlined in this article and using a sample inspection form, you can ensure that your electrical rough-in inspection is thorough and effective.

What is the purpose of an electrical rough-in inspection?

+

The purpose of an electrical rough-in inspection is to ensure that the electrical system is installed correctly and safely, meeting local building codes and regulations.

What components are involved in an electrical rough-in inspection?

+

The components involved in an electrical rough-in inspection include wiring, outlets and switches, panelboards and circuit breakers, and grounding and bonding.

How often should an electrical rough-in inspection be performed?

+

An electrical rough-in inspection should be performed after the electrical wiring, outlets, switches, and other components have been installed, but before the walls are closed up with drywall.