5 Tips Transfer Plates

Introduction to Transfer Plates

Transfer plates are a crucial component in various industrial and manufacturing processes, serving as a medium to transfer items, materials, or products from one location to another. The efficiency and effectiveness of these plates can significantly impact the overall productivity and quality of the output. In this article, we will delve into the world of transfer plates, exploring their types, applications, and most importantly, providing tips on how to transfer plates safely and efficiently.

Understanding Transfer Plates

Before we dive into the tips, it’s essential to understand what transfer plates are and their significance in different industries. Transfer plates can be made from various materials, including metals, plastics, and ceramics, each chosen for its specific properties that make it suitable for particular applications. These plates are used in sectors such as manufacturing, logistics, and even in laboratory settings for handling sensitive materials.

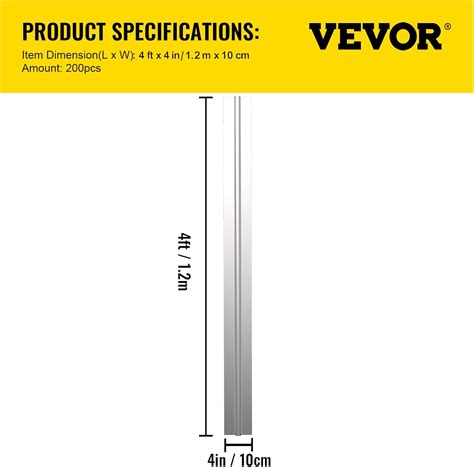

Types of Transfer Plates

There are several types of transfer plates, each designed for specific tasks: - Metal Transfer Plates: Often used in heavy-duty applications due to their strength and durability. - Plastic Transfer Plates: Preferred for their lightweight and resistance to corrosion, making them ideal for applications involving chemicals or moisture. - Ceramic Transfer Plates: Utilized in high-temperature applications or when dealing with highly corrosive materials due to their thermal resistance and chemical inertness.

5 Tips for Transferring Plates

Transferring plates, especially those carrying sensitive or heavy materials, requires careful consideration to prevent accidents, damage to the materials, or injury to personnel. Here are five tips to ensure safe and efficient transfer:

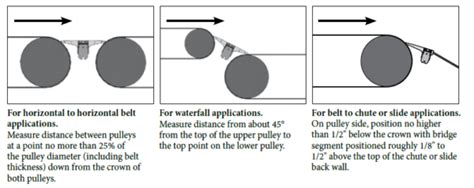

- Assess the Load: Always evaluate the weight and dimensions of the load to be transferred. This assessment helps in choosing the right type of transfer plate and in planning the safest route for the transfer.

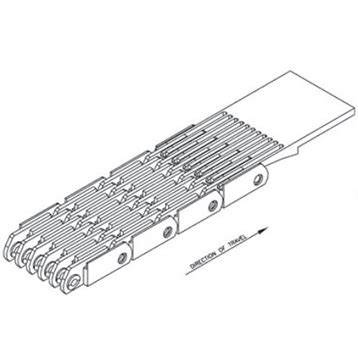

- Choose the Right Equipment: Depending on the type of transfer plate and the material it carries, select appropriate handling equipment. This could range from manual lifting devices for lighter loads to mechanized lifters or conveyors for heavier or bulkier items.

- Ensure Proper Training: Personnel involved in the transfer process should receive adequate training. This includes understanding the properties of the transfer plate, how to handle different materials safely, and being familiar with the equipment used for lifting and moving.

- Plan the Route: Before initiating the transfer, plan the route carefully. Identify potential obstacles, ensure the path is clear, and consider the height and width of doorways, corridors, or any other passage the transfer plate will need to go through.

- Monitor and Adjust: Continuously monitor the transfer process. Be prepared to adjust the plan if unforeseen obstacles arise or if the conditions change. Maintaining flexibility and being able to adapt quickly can prevent accidents and ensure the transfer is completed successfully.

Applications of Transfer Plates

Transfer plates are versatile and find applications in various sectors: - Manufacturing: For moving parts or products through different stages of production. - Logistics: In warehouses for storing and retrieving goods. - Laboratories: For handling chemicals, biological samples, or other sensitive materials.

| Type of Transfer Plate | Common Applications |

|---|---|

| Metal | Heavy-duty manufacturing, construction |

| Plastic | Chemical handling, food processing |

| Ceramic | High-temperature applications, laboratory settings |

📝 Note: Always refer to the manufacturer's guidelines for the specific transfer plate being used, as different materials and designs may have unique handling requirements.

In summary, understanding the different types of transfer plates, their applications, and following tips for safe and efficient transfer can significantly enhance productivity and safety in various industries. By assessing the load, choosing the right equipment, ensuring proper training, planning the route, and monitoring the process, businesses can minimize risks and maximize the benefits of using transfer plates in their operations. The careful selection and handling of transfer plates are crucial for achieving smooth and efficient workflows, whether in manufacturing, logistics, or laboratory settings.