Inspection Paperwork Requirements

Introduction to Inspection Paperwork Requirements

When it comes to inspections, whether they are for vehicles, buildings, or equipment, having the right paperwork in place is crucial. Inspection paperwork serves as a record of the inspection, detailing what was checked, any issues found, and what actions were taken. This not only helps in maintaining compliance with regulations but also provides a trail of evidence in case of disputes or accidents. In this article, we will delve into the details of inspection paperwork requirements, exploring their importance, the types of paperwork needed, and how to ensure compliance.

Importance of Inspection Paperwork

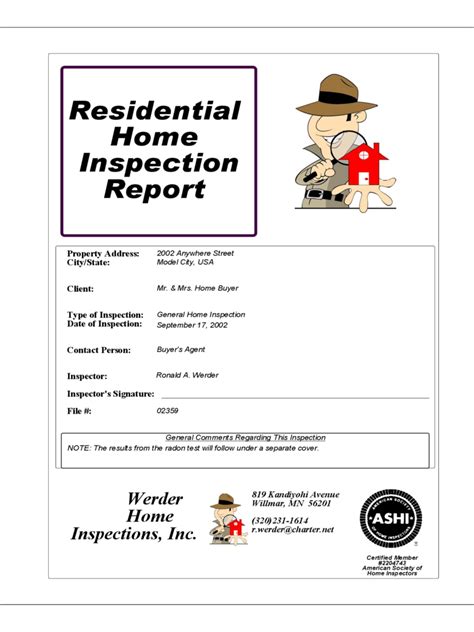

The importance of inspection paperwork cannot be overstated. Compliance with regulations is a key reason, as many industries are subject to strict guidelines that require regular inspections and detailed records. For instance, in the construction industry, inspections are critical to ensure that buildings are safe for occupancy. Similarly, in the automotive sector, vehicle inspections are mandatory to ensure roadworthiness. Beyond compliance, inspection paperwork also serves as a protective measure for both the inspector and the inspected party. It provides a clear record of the inspection’s findings, which can be invaluable in the event of a dispute or if an accident occurs.

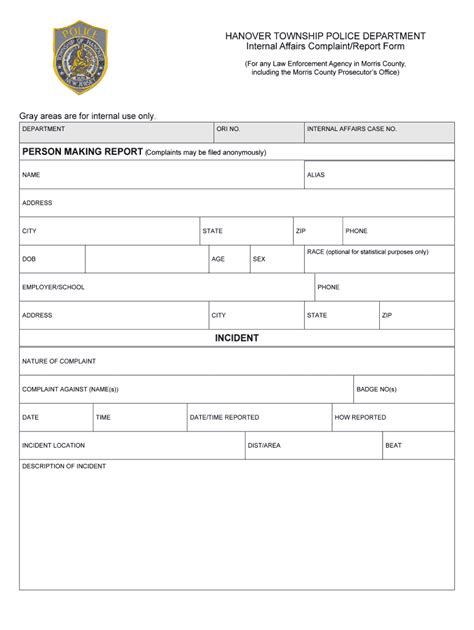

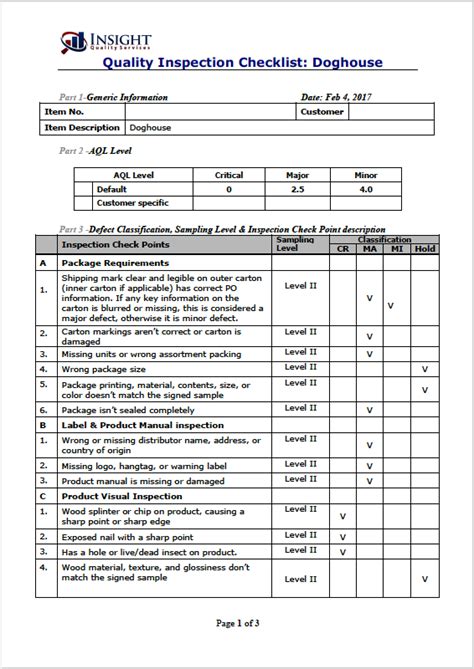

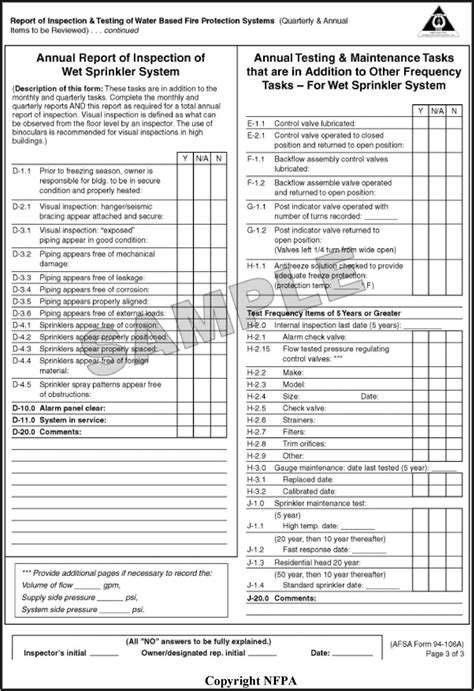

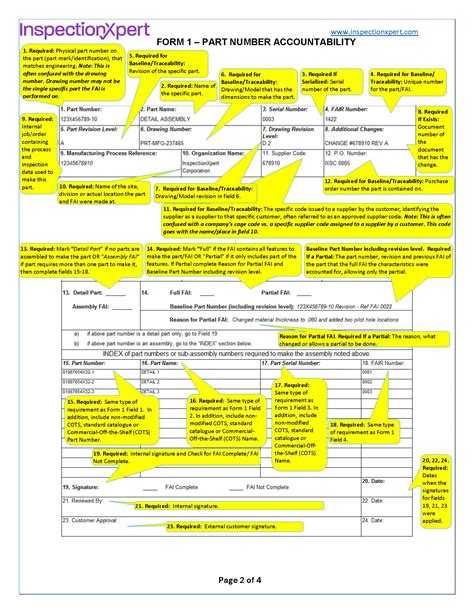

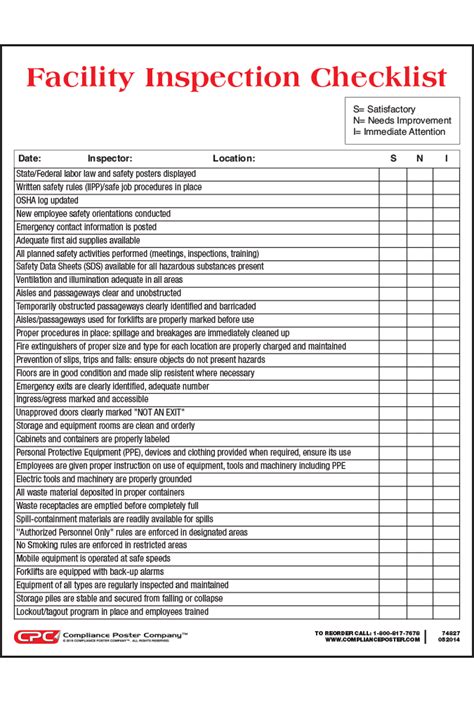

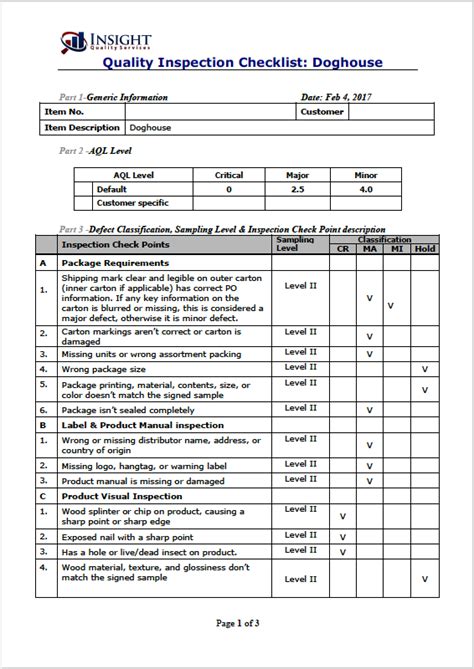

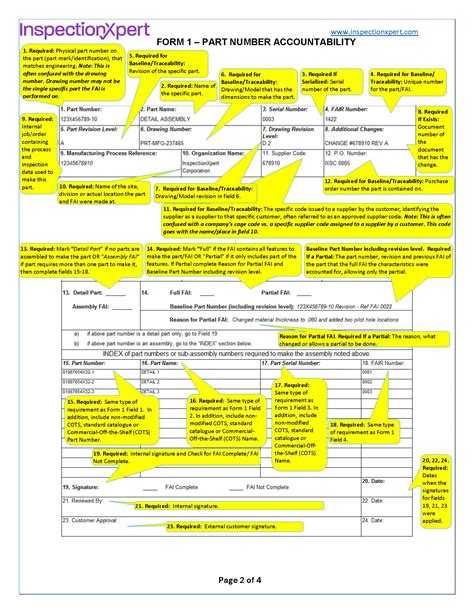

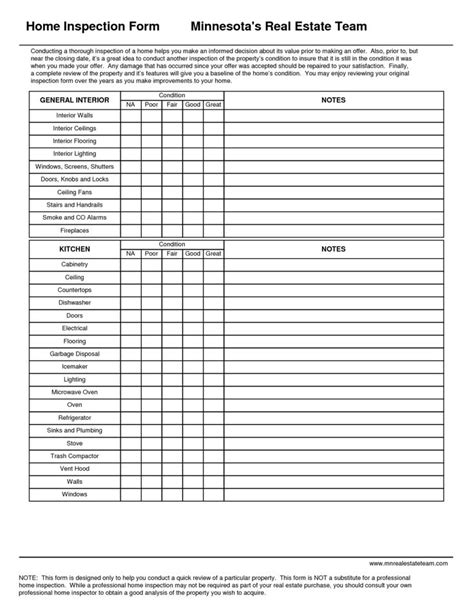

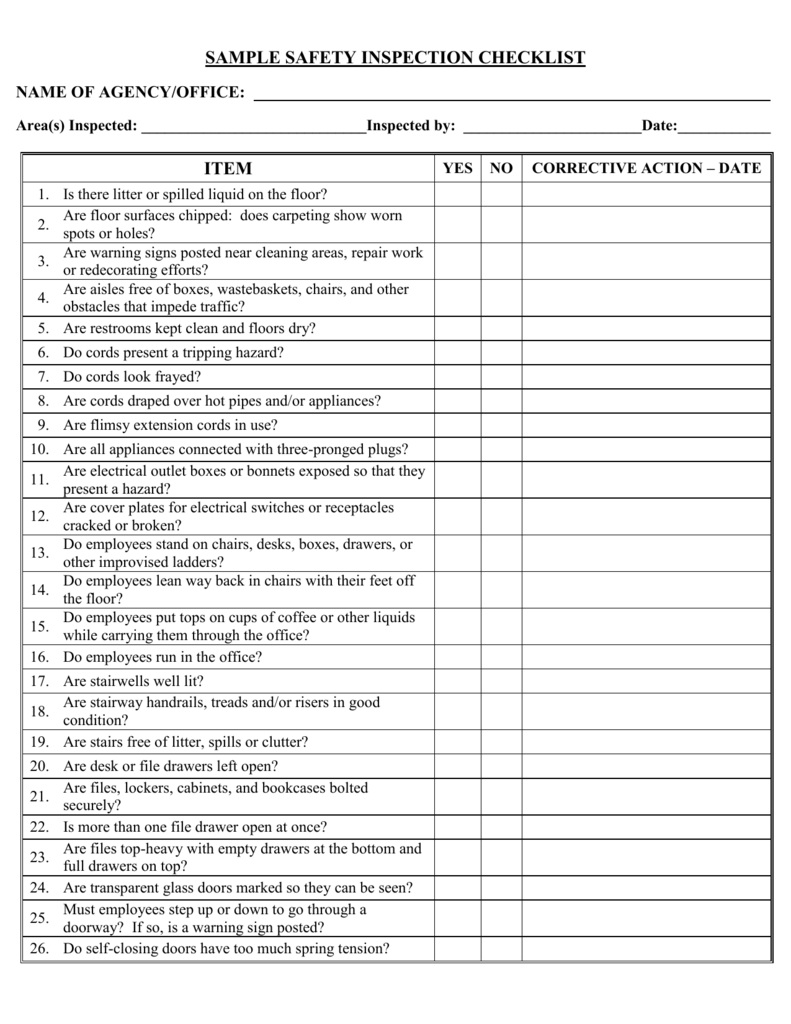

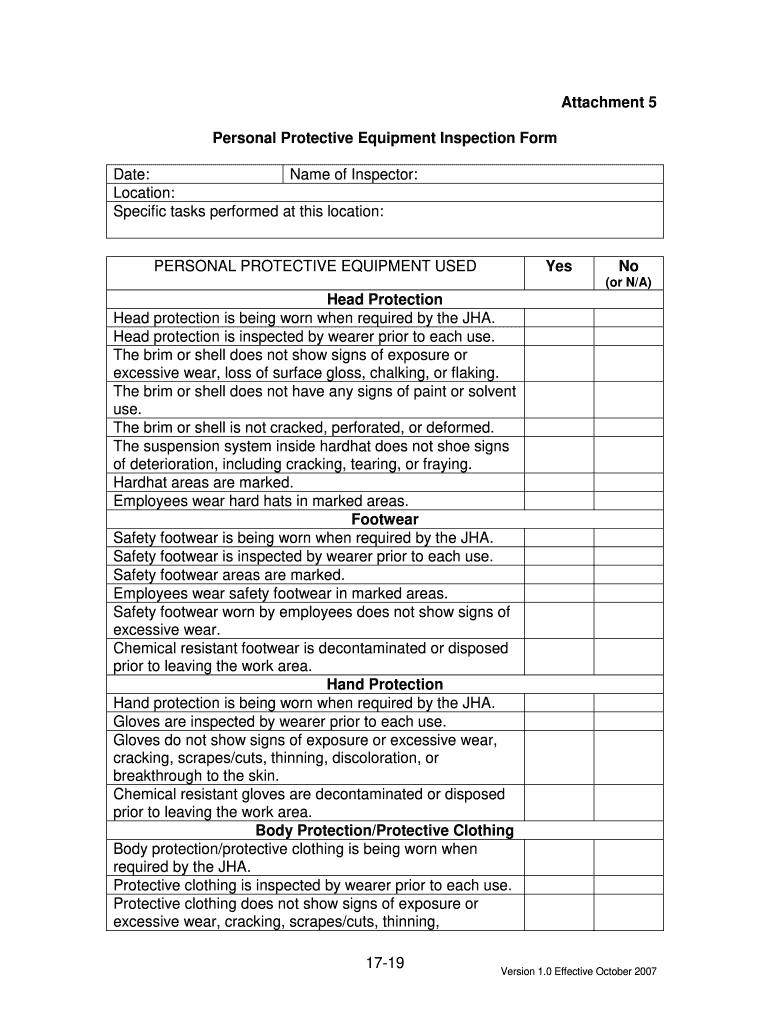

Types of Inspection Paperwork

There are several types of inspection paperwork, each serving a specific purpose: - Pre-inspection forms: These are used to gather information before the inspection, such as the history of the item or area to be inspected. - Inspection checklists: These are detailed lists of what needs to be checked during the inspection. They ensure that nothing is overlooked and provide a standardized method of inspection. - Inspection reports: These documents summarize the findings of the inspection, including any defects or issues found and recommendations for repairs or further action. - Certification documents: In some cases, inspections may result in the issuance of certificates, indicating that the inspected item or area meets certain standards or regulations.

Best Practices for Inspection Paperwork

To ensure that inspection paperwork is effective and compliant with regulations, several best practices should be followed: - Accuracy and completeness: All paperwork should be filled out accurately and completely. Missing information can lead to misunderstandings and compliance issues. - Standardization: Using standardized forms and checklists can help ensure consistency across inspections. - Digital storage: Considering digital storage for inspection paperwork can improve accessibility and reduce the risk of loss or damage to physical documents. - Training: Ensuring that inspectors are properly trained in filling out paperwork and understanding the legal and regulatory requirements is essential.

Technological Advancements in Inspection Paperwork

With the advancement of technology, inspection paperwork is also evolving. Digital inspection tools and mobile apps are becoming increasingly popular, allowing for more efficient and accurate inspections. These tools can provide real-time reporting, automatic generation of inspection reports, and seamless storage of documents. They also reduce the reliance on physical paperwork, minimizing the risk of errors and loss of documents.

Challenges and Future Directions

Despite the advancements, there are still challenges to overcome, such as data security and ensuring that digital systems are compliant with evolving regulations. The future of inspection paperwork likely lies in further integration with technology, possibly incorporating artificial intelligence (AI) and Internet of Things (IoT) devices to enhance inspection processes and data analysis.

💡 Note: As technology continues to advance, it's crucial for industries to stay informed and adapt their inspection paperwork processes accordingly to maintain compliance and efficiency.

Conclusion and Summary

In summary, inspection paperwork is a critical component of any inspection process, serving as a record of compliance, a protective measure, and a tool for quality control. Understanding the different types of inspection paperwork, following best practices, and embracing technological advancements are key to effective inspection management. As industries continue to evolve, the importance of adaptable, compliant, and efficient inspection paperwork systems will only continue to grow.

What is the primary purpose of inspection paperwork?

+

The primary purpose of inspection paperwork is to provide a detailed record of the inspection, including what was checked, any issues found, and actions taken, ensuring compliance with regulations and serving as a protective measure.

What types of inspection paperwork are commonly used?

+

Common types include pre-inspection forms, inspection checklists, inspection reports, and certification documents, each serving a specific purpose in the inspection process.

How is technology impacting inspection paperwork?

+

Technology, such as digital inspection tools and mobile apps, is making inspection paperwork more efficient, accurate, and accessible, while also reducing the reliance on physical documents and enhancing data analysis capabilities.