5 PA Inspection Papers

Introduction to PA Inspection Papers

PA inspection papers are a crucial aspect of the inspection process in various industries, including manufacturing, construction, and quality control. These papers provide a detailed record of the inspection process, including the results, findings, and recommendations for improvement. In this article, we will delve into the world of PA inspection papers, exploring their importance, types, and best practices for creation and implementation.

Importance of PA Inspection Papers

PA inspection papers are essential for several reasons: * They provide a permanent record of the inspection process, which can be used for future reference and auditing purposes. * They help to identify defects and deficiencies in the product or process, allowing for corrective action to be taken. * They enable continuous improvement, by providing a framework for tracking changes and improvements over time. * They facilitate communication between stakeholders, including inspectors, manufacturers, and regulatory bodies.

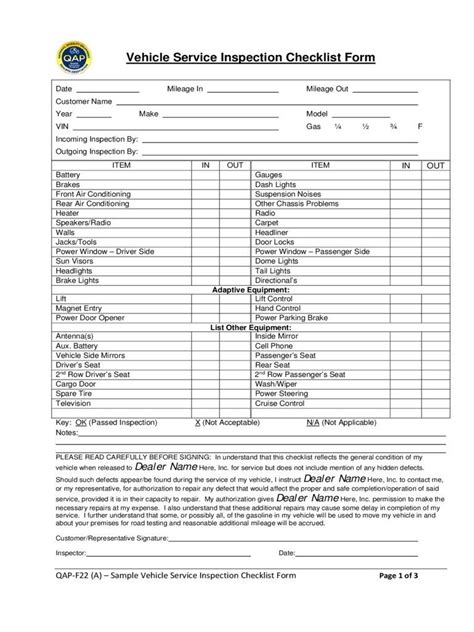

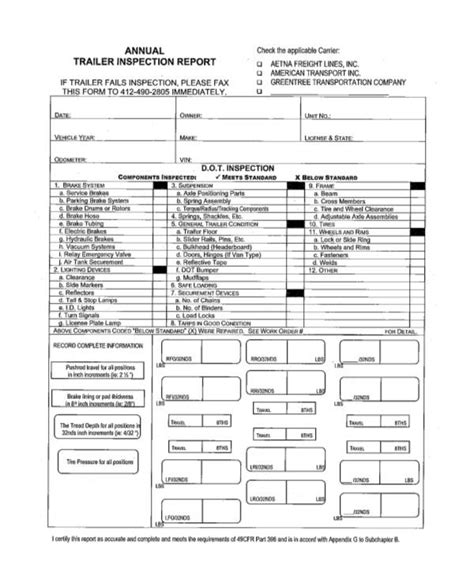

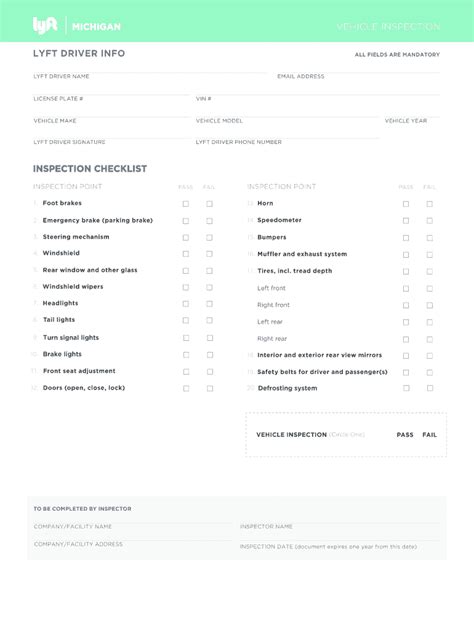

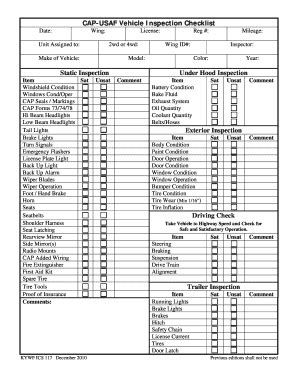

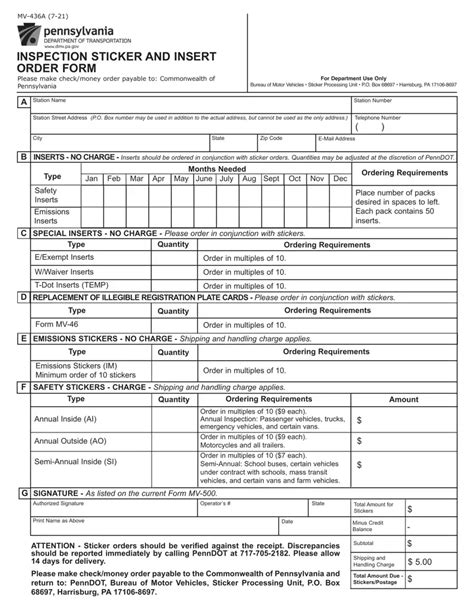

Types of PA Inspection Papers

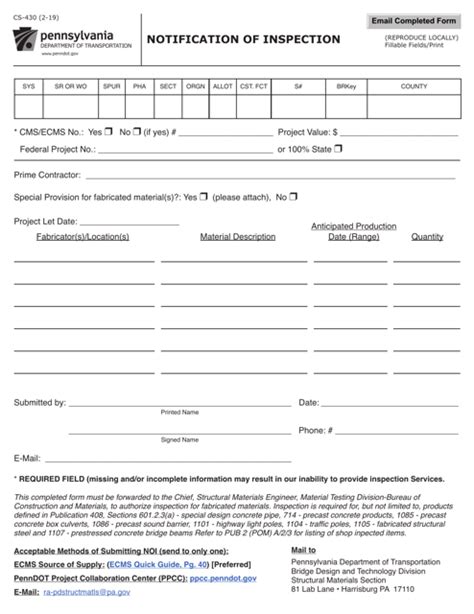

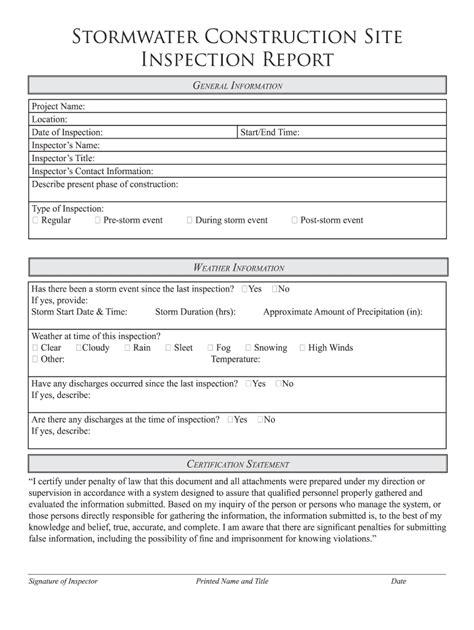

There are several types of PA inspection papers, including: * Checklists: These are pre-defined lists of items to be inspected, which can be used to ensure that all necessary steps are taken during the inspection process. * Inspection reports: These provide a detailed record of the inspection findings, including any defects or deficiencies identified. * Test reports: These provide a record of the results of any tests or examinations conducted during the inspection process. * Certification documents: These provide formal certification that the product or process has met the required standards and regulations.

Best Practices for Creating PA Inspection Papers

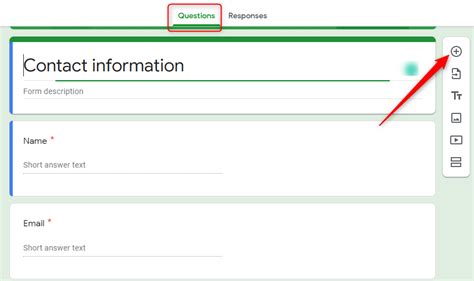

To create effective PA inspection papers, the following best practices should be followed: * Clearly define the scope of the inspection, including the items to be inspected and the standards to be applied. * Use a standardized format, to ensure that all inspection papers are consistent and easy to understand. * Include all necessary information, including the date and time of the inspection, the identity of the inspector, and the results of the inspection. * Use clear and concise language, to avoid confusion or misinterpretation.

Implementation of PA Inspection Papers

To implement PA inspection papers effectively, the following steps should be taken: * Develop a comprehensive inspection plan, which outlines the scope, frequency, and procedures for the inspection. * Train inspectors on the use of PA inspection papers, including the completion of checklists, inspection reports, and test reports. * Establish a system for tracking and recording inspection results, including the use of databases or spreadsheets. * Regularly review and update PA inspection papers, to ensure that they remain relevant and effective.

| Inspection Paper Type | Purpose | Contents |

|---|---|---|

| Checklist | To ensure that all necessary steps are taken during the inspection process | List of items to be inspected, including standards and regulations to be applied |

| Inspection Report | To provide a detailed record of the inspection findings | Date and time of inspection, identity of inspector, results of inspection, including any defects or deficiencies identified |

| Test Report | To provide a record of the results of any tests or examinations conducted during the inspection process | Results of tests or examinations, including any failures or deficiencies identified |

| Certification Document | To provide formal certification that the product or process has met the required standards and regulations | Statement of certification, including the standards and regulations met, and the date and time of certification |

📝 Note: PA inspection papers should be regularly reviewed and updated to ensure that they remain relevant and effective.

In summary, PA inspection papers are a critical component of the inspection process, providing a permanent record of the inspection results and findings. By following best practices for creation and implementation, and using the right types of inspection papers, organizations can ensure that their products and processes meet the required standards and regulations, and that they are able to identify and address any defects or deficiencies. The key points to remember are the importance of PA inspection papers, the different types of inspection papers, and the best practices for creating and implementing them.

What is the purpose of PA inspection papers?

+

The purpose of PA inspection papers is to provide a detailed record of the inspection process, including the results, findings, and recommendations for improvement.

What are the different types of PA inspection papers?

+

The different types of PA inspection papers include checklists, inspection reports, test reports, and certification documents.

How often should PA inspection papers be reviewed and updated?

+

PA inspection papers should be regularly reviewed and updated to ensure that they remain relevant and effective.