5 Backflow Test Steps

Introduction to Backflow Testing

Backflow testing is a crucial process that ensures the safety of drinking water by preventing contaminated water from flowing back into the potable water supply. This is particularly important in residential, commercial, and industrial settings where there are cross-connections between the potable water system and potential sources of contamination. The backflow testing process involves a series of steps designed to identify and mitigate any risks associated with backflow. In this article, we will delve into the 5 key steps involved in backflow testing, highlighting the importance of each step and how they contribute to the overall safety of our water supply.

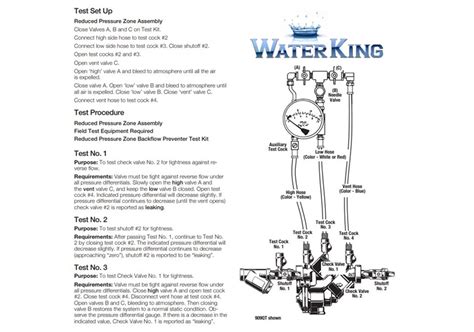

Step 1: Preparation and Assembly of Equipment

The first step in backflow testing involves the preparation and assembly of the necessary equipment. This includes the backflow tester, which is typically a calibrated device designed to measure the pressure differential across the backflow preventer. Other equipment may include hoses, adapters, and gauges, depending on the specific requirements of the test. It is essential to ensure that all equipment is in good working condition and calibrated according to the manufacturer’s instructions. Proper assembly and preparation of the equipment are critical to obtaining accurate test results.

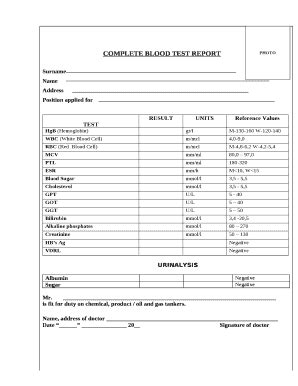

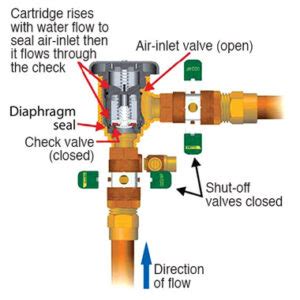

Step 2: Identification of Test Points

The next step involves identifying the test points on the backflow preventer. These test points are specifically designed to allow the tester to measure the pressure differential across the device. The location and number of test points can vary depending on the type of backflow preventer being tested. It is crucial to consult the manufacturer’s instructions or diagrams to correctly identify the test points. Failure to do so can result in inaccurate test results or damage to the backflow preventer.

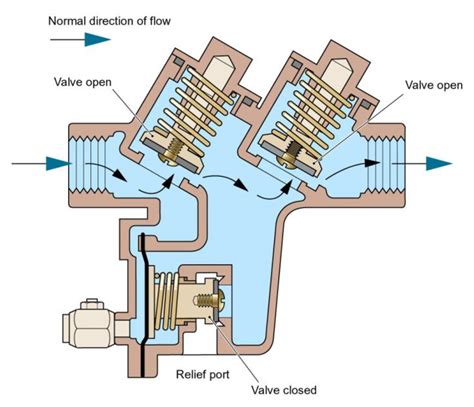

Step 3: Conducting the Test

With the equipment assembled and test points identified, the next step is to conduct the backflow test. This involves attaching the hoses and adapters to the test points and setting up the backflow tester according to the manufacturer’s instructions. The test typically involves a series of steps designed to simulate different flow conditions, including:

- Static pressure test to check for leaks

- Dynamic pressure test to check the operation of the backflow preventer under flow conditions

- Differential pressure test to check the pressure differential across the backflow preventer

Step 4: Analysis of Test Results

After conducting the tests, the next step involves analyzing the results. This includes reviewing the pressure readings and flow rates to determine if the backflow preventer is operating correctly. The analysis of test results requires a good understanding of the backflow preventer’s operation and the acceptable limits for pressure and flow rate. If the results indicate that the backflow preventer is not operating correctly, further investigation and repair may be necessary.

Step 5: Reporting and Documentation

The final step in the backflow testing process involves reporting and documentation. This includes preparing a detailed report of the test results, including any repairs or maintenance that were performed. Accurate and comprehensive documentation is essential for regulatory compliance and for maintaining a record of the backflow preventer’s history. The report should include information such as:

| Test Date | Test Results | Repairs/ Maintenance |

|---|---|---|

| Insert Date | Insert Results | Insert Repairs/ Maintenance |

This information is critical for ensuring that the backflow preventer continues to operate correctly and that any potential risks are mitigated.

📝 Note: It is essential to follow local regulations and guidelines for backflow testing, as these may vary depending on the jurisdiction.

In summary, backflow testing is a critical process that involves a series of steps designed to ensure the safety of our drinking water. By following these 5 steps, individuals can ensure that their backflow preventers are operating correctly and that any potential risks are mitigated. The importance of backflow testing cannot be overstated, as it plays a critical role in protecting public health. As we conclude this discussion on backflow testing, it is clear that this process is essential for maintaining the integrity of our water supply and ensuring the health and safety of our communities.

What is the purpose of backflow testing?

+

The purpose of backflow testing is to ensure that the backflow preventer is operating correctly and that contaminated water is not entering the potable water supply.

How often should backflow testing be performed?

+

The frequency of backflow testing depends on local regulations and guidelines, but it is typically performed annually.

What are the consequences of not performing backflow testing?

+

The consequences of not performing backflow testing can include contaminated drinking water, regulatory fines, and damage to the water supply infrastructure.