5 PA Inspection Papers

Introduction to 5 PA Inspection Papers

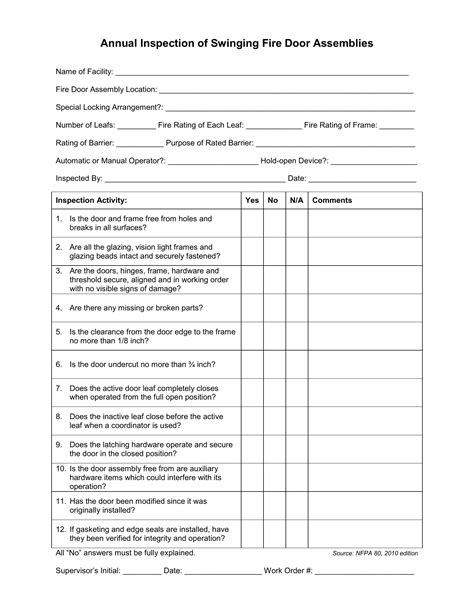

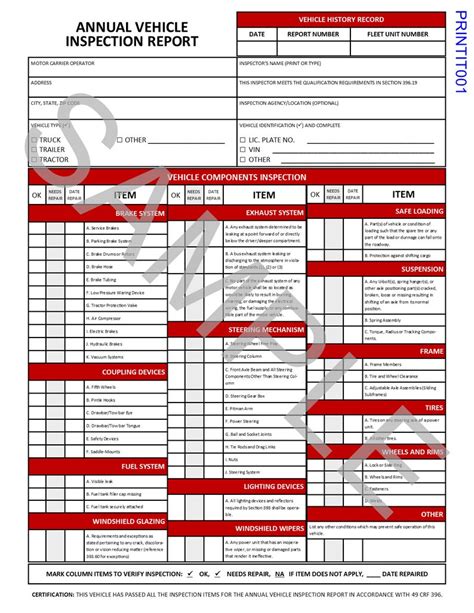

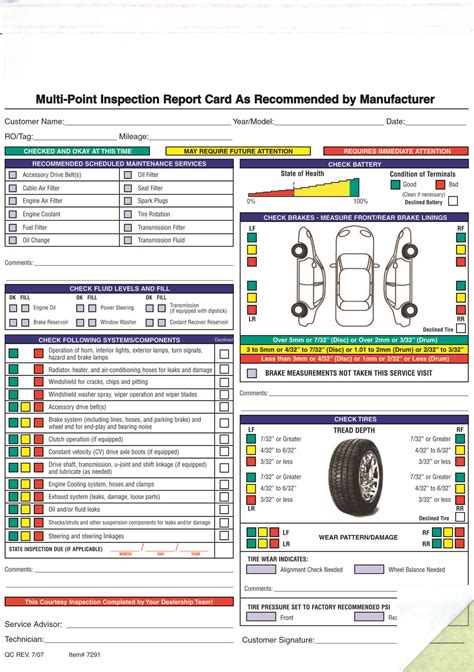

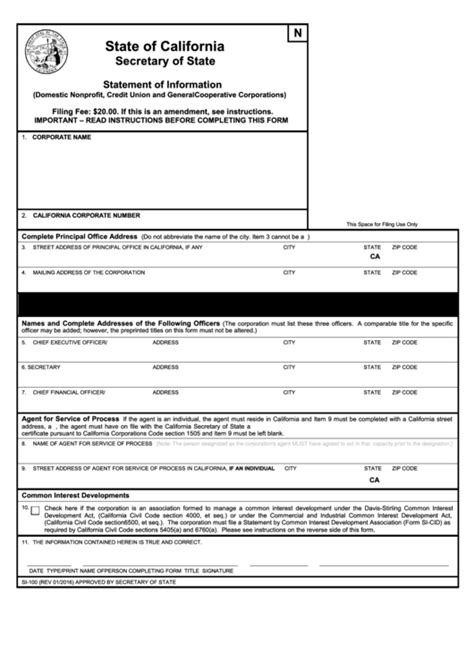

The 5 PA inspection papers are a crucial component of the quality control process in various industries, including manufacturing, construction, and healthcare. These papers provide a standardized framework for inspecting and evaluating products, processes, and systems to ensure they meet specific requirements and standards. In this article, we will delve into the world of 5 PA inspection papers, exploring their purpose, benefits, and applications.

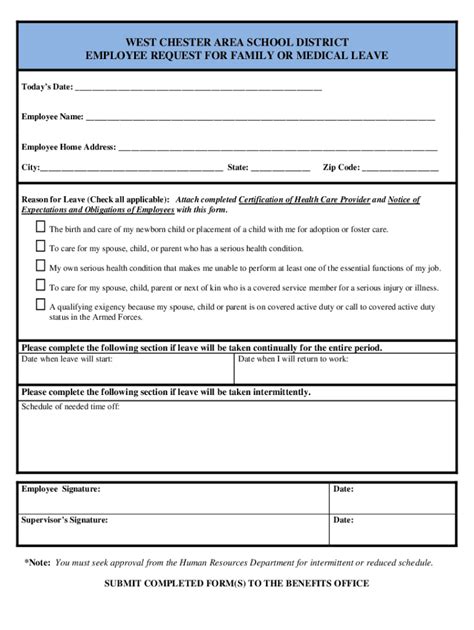

What are 5 PA Inspection Papers?

5 PA inspection papers are documents that outline the procedures and protocols for conducting inspections and audits. The term “5 PA” refers to the five primary components of these papers: * Plan: Outlining the scope, objectives, and methodology of the inspection * Audit: Conducting a thorough examination of the product, process, or system * Analysis: Evaluating the data and findings from the inspection * Action: Identifying and implementing corrective actions to address any defects or non-conformities * Authentication: Verifying the effectiveness of the corrective actions and ensuring that the product, process, or system meets the required standards

Benefits of 5 PA Inspection Papers

The use of 5 PA inspection papers offers numerous benefits, including: * Improved quality: By identifying and addressing defects and non-conformities, organizations can ensure that their products, processes, and systems meet the required standards. * Increased efficiency: The standardized framework provided by 5 PA inspection papers streamlines the inspection process, reducing the time and resources required. * Enhanced customer satisfaction: By ensuring that products and services meet customer requirements, organizations can improve customer satisfaction and loyalty. * Reduced costs: By identifying and addressing defects and non-conformities early on, organizations can avoid costly rework and repairs.

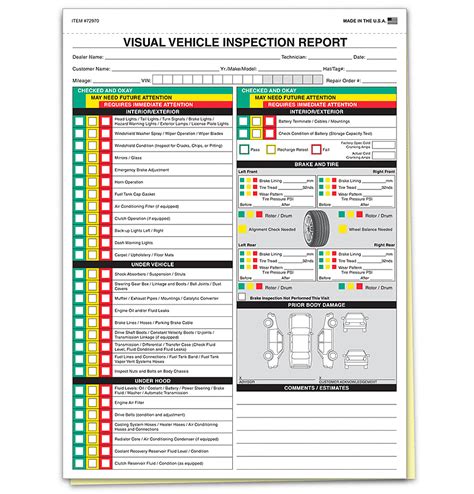

Applications of 5 PA Inspection Papers

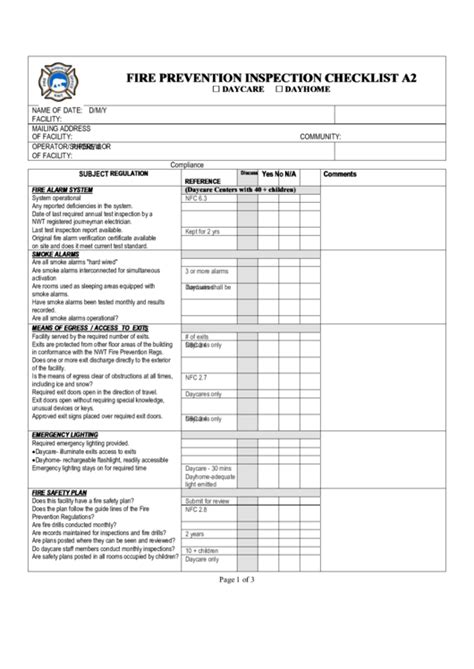

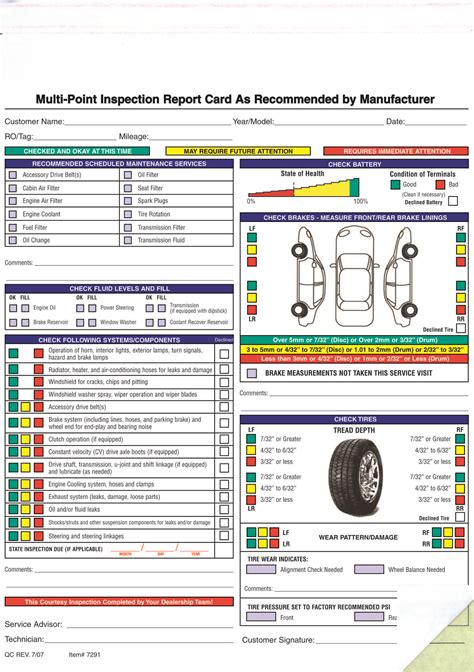

5 PA inspection papers have a wide range of applications across various industries, including: * Manufacturing: Inspecting products and processes to ensure compliance with regulatory requirements and industry standards. * Construction: Inspecting buildings, infrastructure, and other construction projects to ensure compliance with building codes and regulations. * Healthcare: Inspecting medical devices, equipment, and facilities to ensure compliance with regulatory requirements and industry standards. * Food processing: Inspecting food products and processes to ensure compliance with food safety regulations and industry standards.

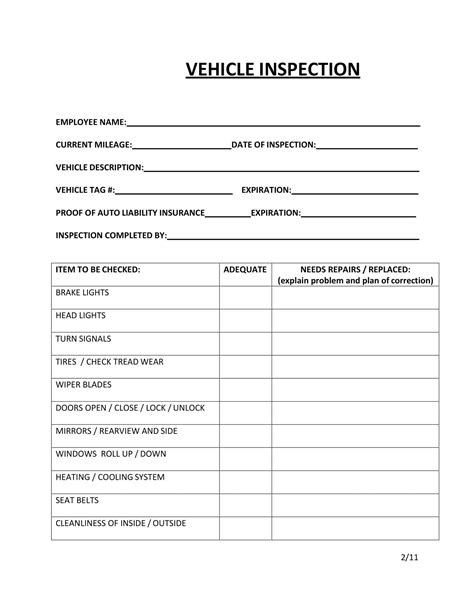

How to Create 5 PA Inspection Papers

Creating 5 PA inspection papers involves several steps: * Define the scope and objectives: Identify the product, process, or system to be inspected and outline the objectives of the inspection. * Develop the inspection plan: Outline the procedures and protocols for conducting the inspection, including the methods and tools to be used. * Conduct the inspection: Carry out the inspection, collecting data and identifying any defects or non-conformities. * Analyze the data: Evaluate the data and findings from the inspection, identifying any trends or patterns. * Take action: Identify and implement corrective actions to address any defects or non-conformities.

📝 Note: The creation of 5 PA inspection papers should be a collaborative effort, involving stakeholders from various departments and levels of the organization.

Best Practices for Using 5 PA Inspection Papers

To get the most out of 5 PA inspection papers, organizations should follow best practices, including: * Regularly reviewing and updating the papers: Ensuring that the papers remain relevant and effective. * Providing training and support: Ensuring that personnel are trained and supported in the use of the papers. * Continuously monitoring and evaluating: Continuously monitoring and evaluating the effectiveness of the papers and making improvements as needed.

| Industry | Application |

|---|---|

| Manufacturing | Inspecting products and processes |

| Construction | Inspecting buildings and infrastructure |

| Healthcare | Inspecting medical devices and equipment |

| Food processing | Inspecting food products and processes |

In summary, 5 PA inspection papers are a valuable tool for ensuring quality and compliance in various industries. By understanding the purpose, benefits, and applications of these papers, organizations can create effective inspection papers that meet their specific needs. By following best practices and continuously monitoring and evaluating the effectiveness of the papers, organizations can ensure that their products, processes, and systems meet the required standards, resulting in improved quality, increased efficiency, and enhanced customer satisfaction.

What are the benefits of using 5 PA inspection papers?

+

The benefits of using 5 PA inspection papers include improved quality, increased efficiency, enhanced customer satisfaction, and reduced costs.

How do I create 5 PA inspection papers?

+

Creating 5 PA inspection papers involves defining the scope and objectives, developing the inspection plan, conducting the inspection, analyzing the data, and taking action.

What industries can use 5 PA inspection papers?

+

5 PA inspection papers can be used in various industries, including manufacturing, construction, healthcare, and food processing.