Paperwork

5 Steps To Temps

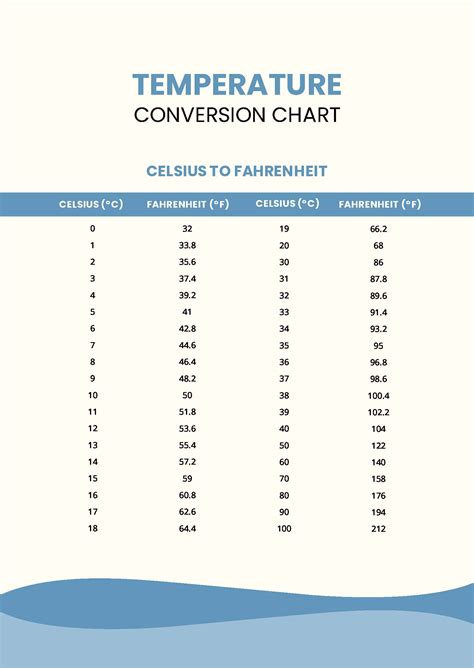

Introduction to Temperature Control

Temperature control is a critical aspect of various industries, including manufacturing, pharmaceuticals, and food processing. Maintaining the right temperature is essential to ensure the quality, safety, and efficiency of products and processes. In this article, we will explore the concept of temperature control, its importance, and provide a step-by-step guide on how to achieve optimal temperature conditions.

Understanding Temperature Control

Temperature control refers to the process of regulating and maintaining a specific temperature range to achieve a desired outcome. This can involve heating, cooling, or insulating objects, materials, or environments to prevent temperature fluctuations. Accurate temperature control is crucial in many applications, as it can affect the physical, chemical, and biological properties of materials and products.

5 Steps to Achieve Optimal Temperature Control

To achieve optimal temperature control, follow these five steps: * Step 1: Define Temperature Requirements: Determine the ideal temperature range for your specific application. This may involve researching industry standards, consulting with experts, or conducting experiments to identify the optimal temperature conditions. * Step 2: Choose Temperature Control Equipment: Select the appropriate temperature control equipment, such as thermocouples, thermistors, or temperature controllers. Consider factors like accuracy, reliability, and compatibility with your specific application. * Step 3: Calibrate Temperature Control Systems: Calibrate your temperature control systems to ensure accuracy and precision. This may involve adjusting settings, configuring software, or performing routine maintenance tasks. * Step 4: Monitor and Control Temperature: Continuously monitor temperature readings and adjust control settings as needed. This may involve using data logging software, alarms, or notifications to alert you to temperature deviations. * Step 5: Validate Temperature Control: Validate your temperature control system by verifying its performance and accuracy. This may involve conducting tests, analyzing data, or seeking third-party certification.

Temperature Control Equipment and Technologies

Various temperature control equipment and technologies are available, including:

| Equipment/Technology | Description |

|---|---|

| Thermocouples | Sensors that measure temperature using a thermoelectric effect |

| Thermistors | Sensors that measure temperature using a resistance-temperature relationship |

| Temperature Controllers | Devices that regulate temperature using feedback control loops |

📝 Note: When selecting temperature control equipment, consider factors like accuracy, reliability, and compatibility with your specific application.

Best Practices for Temperature Control

To ensure effective temperature control, follow these best practices: * Regularly maintain and calibrate temperature control equipment to prevent drift and ensure accuracy. * Use high-quality temperature control equipment and materials to minimize errors and variability. * Monitor temperature readings continuously and adjust control settings as needed to prevent deviations. * Document temperature control procedures and results to ensure transparency and accountability.

In the end, achieving optimal temperature control requires careful planning, attention to detail, and a commitment to excellence. By following these steps and best practices, you can ensure the quality, safety, and efficiency of your products and processes. The ability to control temperature with precision and accuracy is crucial in many industries, and mastering this skill can lead to significant improvements in productivity and results.