5 QCD Forms Needed

Introduction to Quality Control Documents (QCD)

Quality control is a crucial aspect of any manufacturing or production process. It ensures that products meet the required standards and are safe for consumption or use. One of the key components of quality control is the use of Quality Control Documents (QCD). These documents provide a systematic approach to monitoring and controlling the quality of products throughout the production process. In this blog post, we will discuss the importance of QCD forms and the five essential forms needed for effective quality control.

What are QCD Forms?

QCD forms are documents used to record and track quality control data during the production process. They provide a standardized method for collecting and analyzing data, which helps to identify potential quality issues and implement corrective actions. QCD forms can be used in various industries, including food processing, pharmaceuticals, and manufacturing.

Importance of QCD Forms

The use of QCD forms is essential for ensuring the quality of products. Some of the benefits of using QCD forms include: * Improved quality control: QCD forms help to identify potential quality issues and implement corrective actions, ensuring that products meet the required standards. * Increased efficiency: QCD forms provide a standardized method for collecting and analyzing data, which helps to streamline the quality control process. * Reduced costs: By identifying and addressing quality issues early, QCD forms can help to reduce costs associated with rework, scrap, and recalls. * Enhanced customer satisfaction: QCD forms help to ensure that products meet customer requirements, leading to increased customer satisfaction and loyalty.

5 Essential QCD Forms Needed

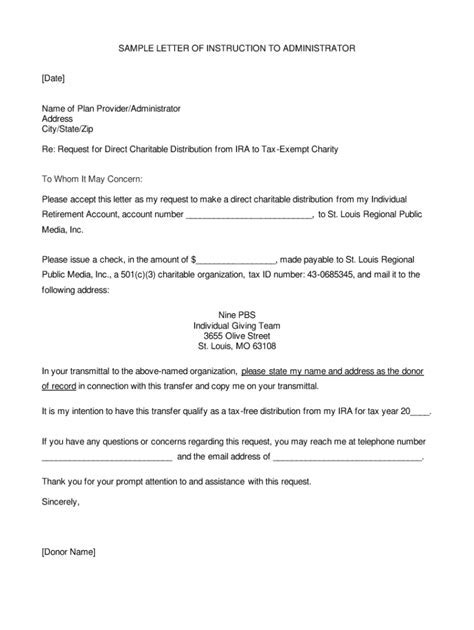

The following are five essential QCD forms needed for effective quality control: * Form 1: Quality Control Checklist: This form is used to verify that all quality control procedures have been followed during the production process. * Form 2: Inspection Report: This form is used to record the results of inspections and tests performed on products during the production process. * Form 3: Defect Report: This form is used to record and track defects found during the production process. * Form 4: Corrective Action Report: This form is used to document corrective actions taken to address quality issues identified during the production process. * Form 5: Quality Control Record: This form is used to record and track quality control data over time, providing a historical record of quality control activities.

📝 Note: These forms should be tailored to meet the specific needs of your organization and industry.

Best Practices for Implementing QCD Forms

To ensure the effective implementation of QCD forms, the following best practices should be followed: * Develop clear and concise forms that are easy to understand and use. * Train personnel on the use of QCD forms and the importance of quality control. * Establish a system for reviewing and updating QCD forms regularly. * Use technology to automate the quality control process and improve efficiency.

| Form | Description | Frequency |

|---|---|---|

| Quality Control Checklist | Verify that all quality control procedures have been followed | Daily |

| Inspection Report | Record the results of inspections and tests | Weekly |

| Defect Report | Record and track defects found during production | Monthly |

| Corrective Action Report | Document corrective actions taken to address quality issues | Quarterly |

| Quality Control Record | Record and track quality control data over time | Annually |

In summary, QCD forms are a crucial component of quality control, providing a systematic approach to monitoring and controlling the quality of products. The five essential QCD forms needed for effective quality control are the Quality Control Checklist, Inspection Report, Defect Report, Corrective Action Report, and Quality Control Record. By implementing these forms and following best practices, organizations can ensure the quality of their products and improve customer satisfaction.

What is the purpose of QCD forms?

+

The purpose of QCD forms is to provide a systematic approach to monitoring and controlling the quality of products during the production process.

How often should QCD forms be reviewed and updated?

+

QCD forms should be reviewed and updated regularly to ensure that they remain relevant and effective.

Can QCD forms be automated using technology?

+

Yes, QCD forms can be automated using technology, such as software and digital platforms, to improve efficiency and reduce errors.