5 Inspection Papers Needed

Introduction to Inspection Papers

When it comes to ensuring the quality and reliability of products, services, or processes, inspection papers play a crucial role. These documents serve as a checklist or a guide to verify that all necessary steps have been taken to meet the required standards. In various industries, including manufacturing, construction, and healthcare, inspection papers are essential for maintaining consistency and preventing errors. This article will delve into the world of inspection papers, highlighting their importance, types, and applications.

Types of Inspection Papers

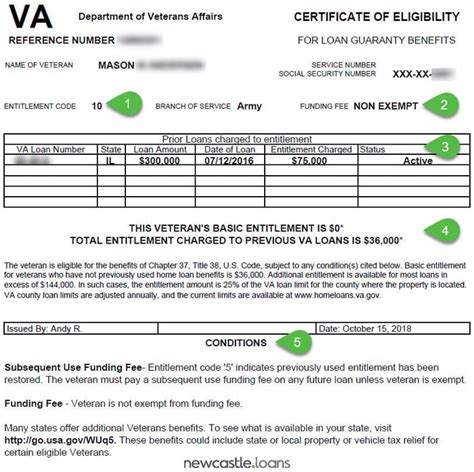

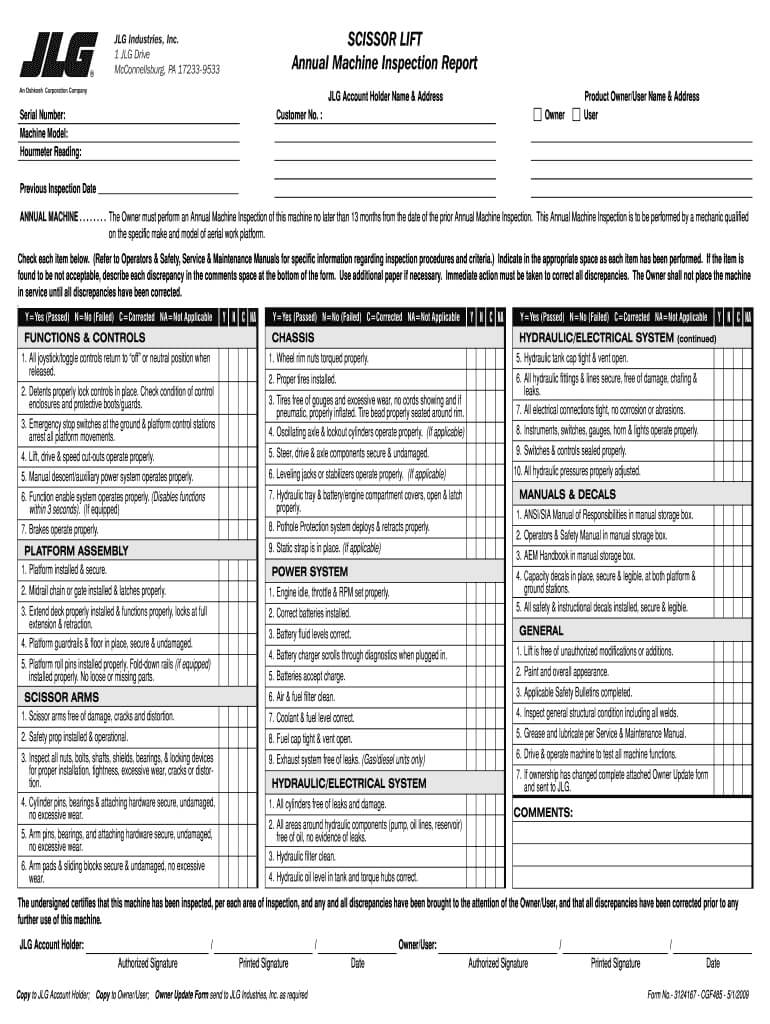

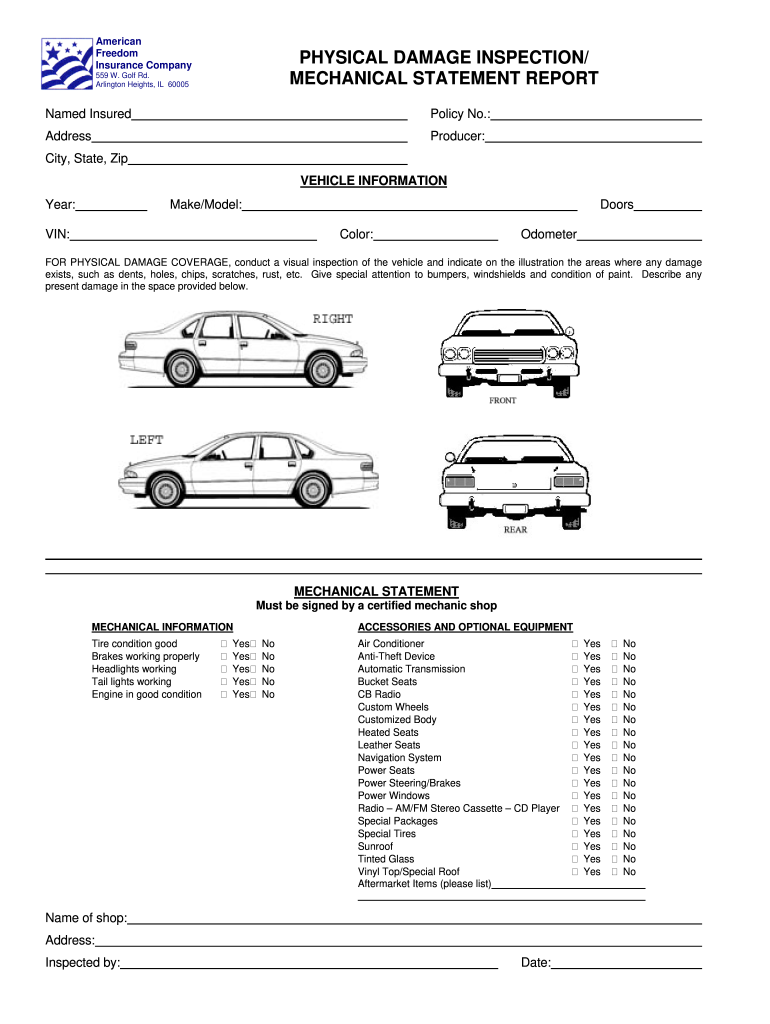

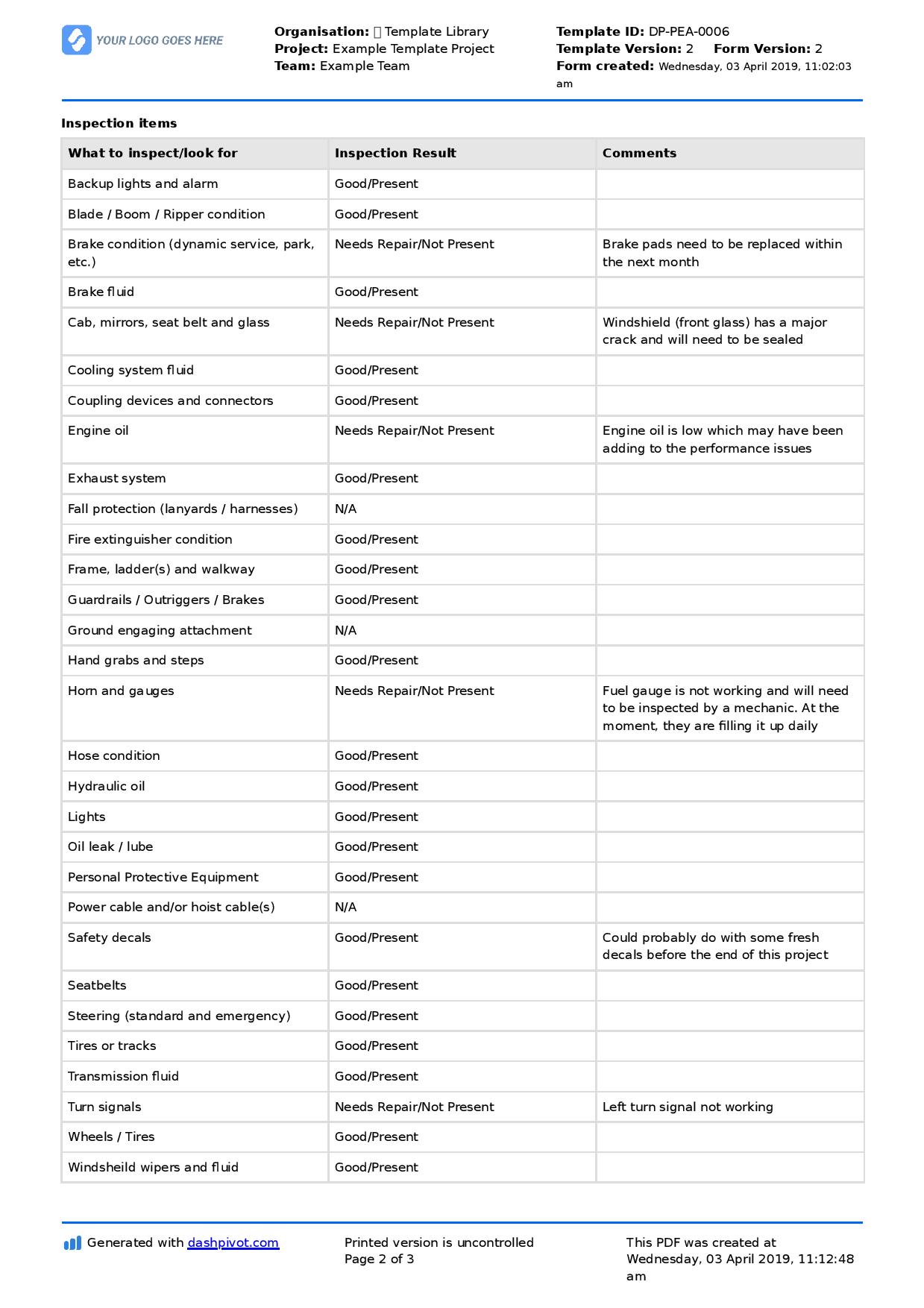

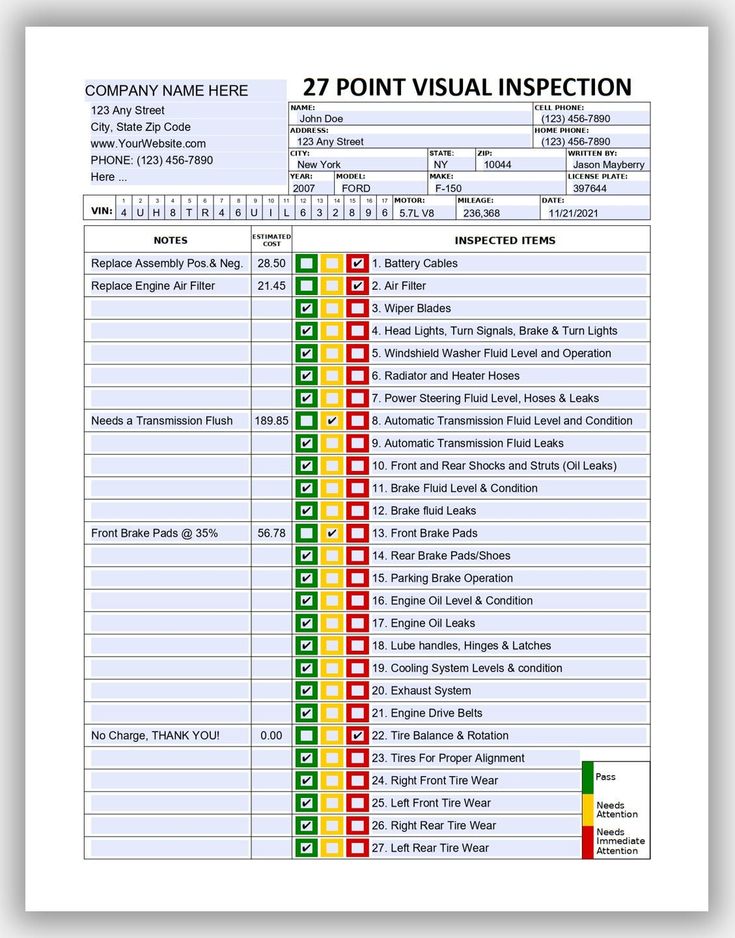

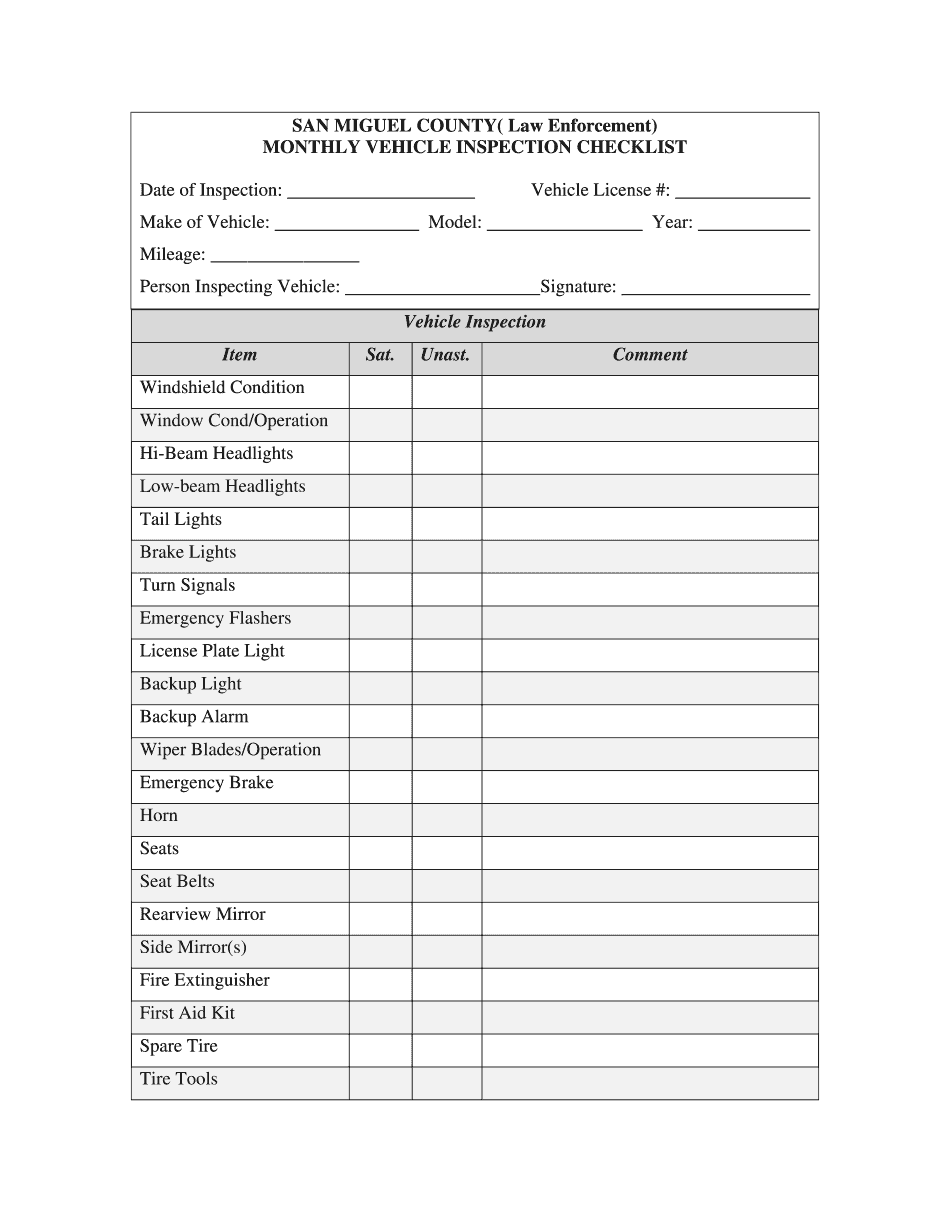

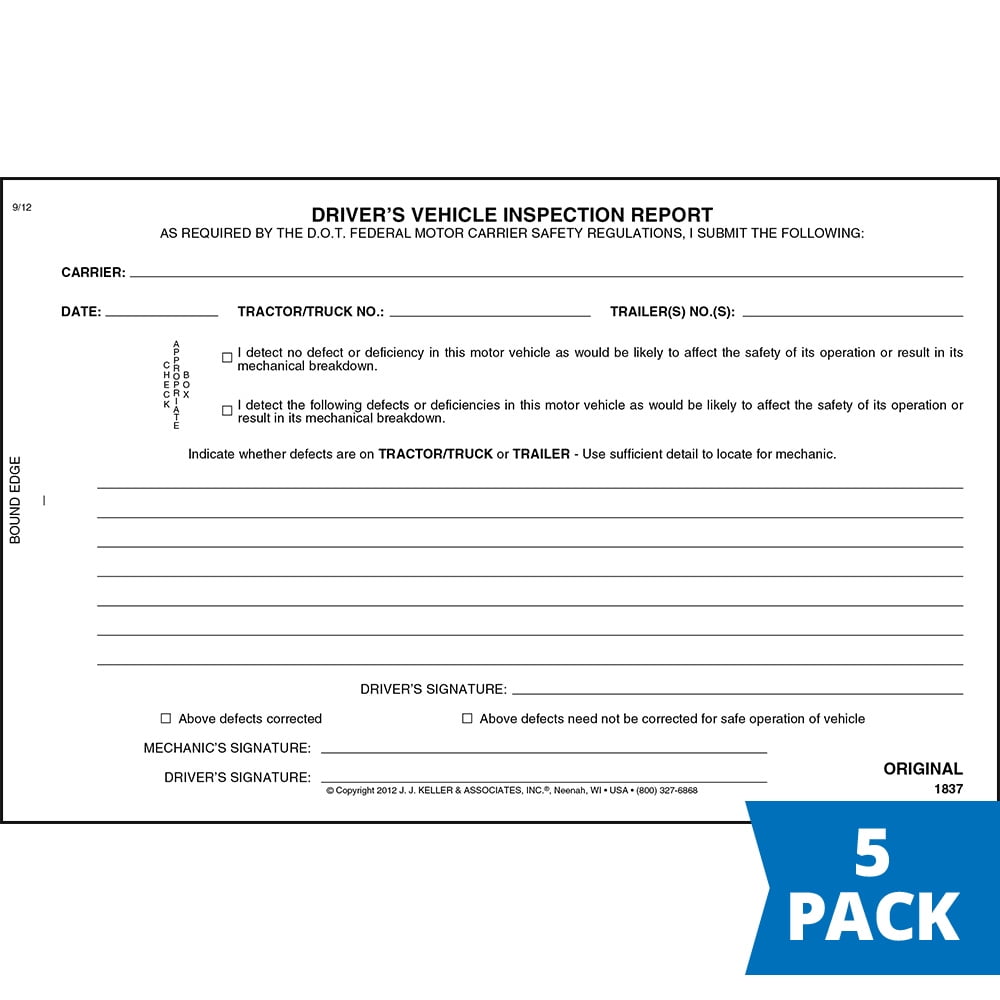

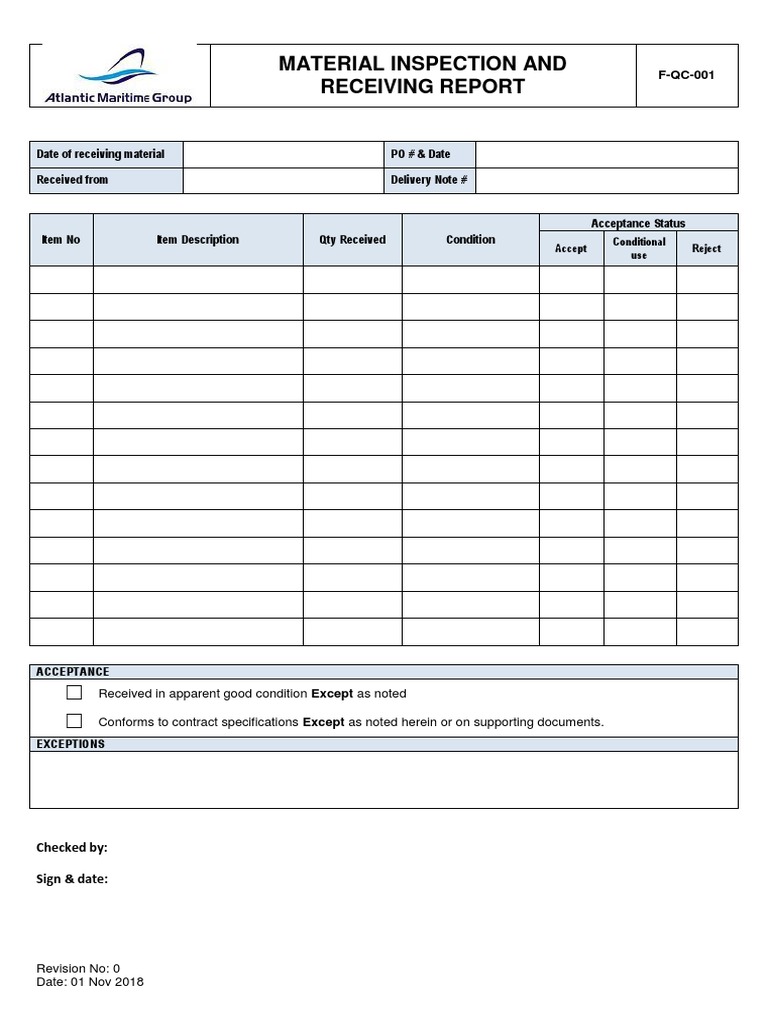

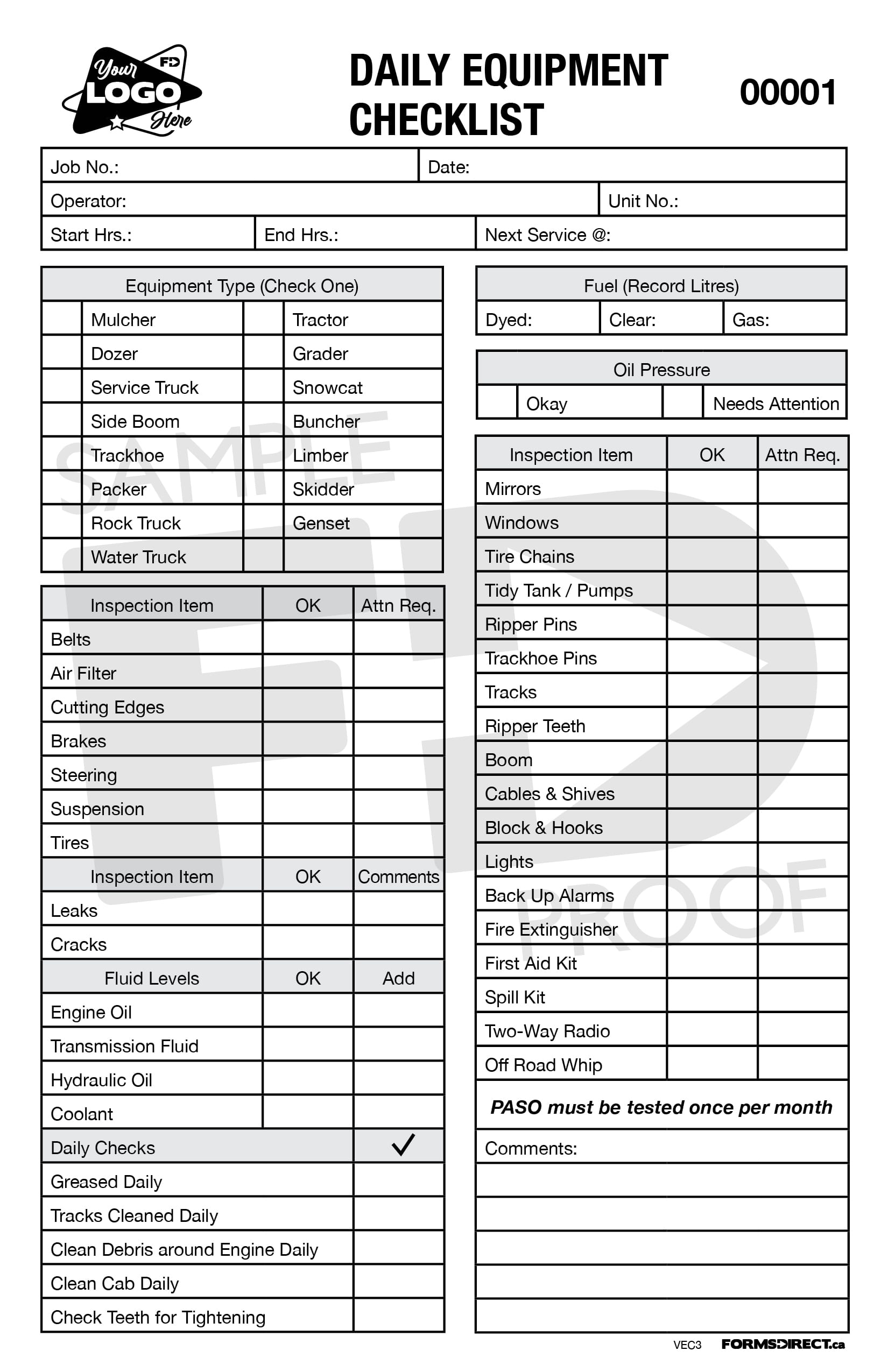

There are several types of inspection papers, each designed to cater to specific needs and industries. Some of the most common types include: - Pre-shipment inspection papers: Used to verify the quality and quantity of goods before they are shipped to customers. - Quality control inspection papers: Focus on ensuring that products meet the required quality standards during the production process. - Compliance inspection papers: Designed to verify that products or services comply with regulatory requirements and industry standards. - Maintenance inspection papers: Used to schedule and record maintenance activities to prevent equipment failure and ensure continuous operation. - Audit inspection papers: Utilized during audits to assess the effectiveness of quality management systems and identify areas for improvement.

Importance of Inspection Papers

The significance of inspection papers cannot be overstated. They offer numerous benefits, including: - Improved quality: By ensuring that all products or services meet the required standards, inspection papers help maintain high quality. - Reduced errors: Systematic checks and balances reduce the likelihood of errors and defects. - Enhanced safety: Inspection papers can identify potential safety hazards, thereby preventing accidents and ensuring a safe working environment. - Compliance with regulations: Inspection papers help organizations comply with regulatory requirements, reducing the risk of legal issues and fines. - Increased efficiency: By streamlining the inspection process, inspection papers can lead to time and cost savings.

Creating Effective Inspection Papers

To create effective inspection papers, several factors must be considered: - Clear objectives: The purpose and scope of the inspection should be clearly defined. - Relevant checkpoints: Inspection papers should include all necessary checkpoints to ensure thoroughness. - Easy to use: The format should be user-friendly to facilitate smooth inspections. - Flexibility: Inspection papers should be adaptable to different situations and environments. - Review and update: Regular review and update of inspection papers are crucial to ensure they remain relevant and effective.

Applications of Inspection Papers

Inspection papers have a wide range of applications across various industries: - Manufacturing: To ensure the quality of products and compliance with industry standards. - Construction: To verify the safety and quality of buildings and infrastructure projects. - Healthcare: To maintain high standards of patient care and comply with regulatory requirements. - Transportation: To ensure the safety and maintenance of vehicles and equipment. - Food industry: To guarantee the quality and safety of food products.

Best Practices for Using Inspection Papers

To maximize the benefits of inspection papers, the following best practices should be adopted: - Training: Ensure that all personnel involved in the inspection process are adequately trained. - Documentation: Maintain accurate and detailed records of inspections. - Follow-up actions: Implement corrective actions based on inspection findings. - Continuous improvement: Regularly review and refine inspection papers to reflect changing needs and standards. - Technology integration: Consider using digital inspection papers and tools to enhance efficiency and accessibility.

📝 Note: The effectiveness of inspection papers largely depends on their proper implementation and continuous review.

Common Challenges and Solutions

Despite their importance, inspection papers can present several challenges, including: - Resistance to change: Overcoming resistance from personnel who are accustomed to traditional methods. - Lack of resources: Insufficient time, budget, or personnel to dedicate to the inspection process. - Complexity: Dealing with complex products or processes that require specialized knowledge. Solutions to these challenges include providing training, allocating necessary resources, and simplifying inspection papers to make them more accessible.

| Type of Inspection Paper | Industry | Purpose |

|---|---|---|

| Pre-shipment inspection papers | Manufacturing | Quality verification before shipment |

| Quality control inspection papers | Construction | Ensuring compliance with building codes |

| Compliance inspection papers | Healthcare | Verification of regulatory compliance |

In summary, inspection papers are vital tools for ensuring quality, safety, and compliance across various industries. Their importance cannot be overstated, and their effective creation and use can lead to significant benefits, including improved quality, reduced errors, and enhanced safety. By understanding the types, applications, and best practices related to inspection papers, organizations can better leverage these documents to achieve their goals and maintain high standards.

What are the main types of inspection papers?

+

The main types of inspection papers include pre-shipment inspection papers, quality control inspection papers, compliance inspection papers, maintenance inspection papers, and audit inspection papers.

Why are inspection papers important in the manufacturing industry?

+

Inspection papers are crucial in the manufacturing industry for ensuring the quality of products, reducing errors, and complying with regulatory requirements, which ultimately leads to customer satisfaction and brand reputation.

How can inspection papers be made more effective?

+

Inspection papers can be made more effective by ensuring they are clear, relevant, and easy to use, and by implementing a system for regular review and update to reflect changing standards and needs.